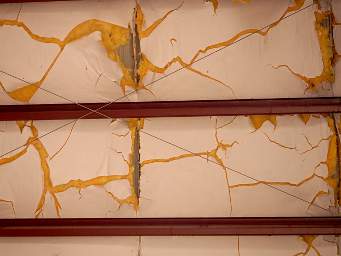

temperature stress on

brittle pvc covering

Metal buildings appear everywhere, as shops, barns, riding arenas, and warehouses. When constructing one or contracting to have one built, an option is to install insulation. It sounds like a good idea. Perhaps it is, under some circumstances. But one should definitely seriously consider the downsides before opting to install it.

We live in west-central Montana, and our climate has rather extreme swings in temperature -- from -40 F to +104 F over the course of a year. In addition, we have a rather dry climate in general. While those temperature extremes and humidity conditions probably play a part in the outcomes we are seeing, I doubt seriously if they matter much over the long term.

Typical metal building insulation comes in the form of fiberglas batts which are installed between the outside sheeting (roof or wall metal) and the metal purlins or studs to which the sheeting is screwed. The batts consist of an insulating material, usually fiberglass, encased in a pvc or similar plastic tube.

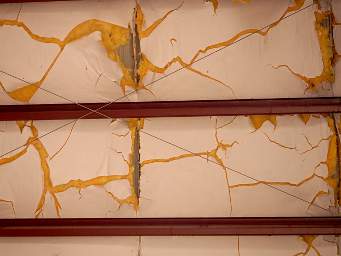

The problem is with the outside casing of the insulation. Virtually all petroleum products fatigue over time. In the case of the insulating batts, the fatigue eventually results in the plastic jacket splitting. That leads to it sagging, and with normal weathering and the occasional bird, you are soon left with an incredible mess of insulation raining down on a slow but steady basis.

As the photos below show, it's not pretty. The insulation makes a constant mess, on a daily basis as flecks and pieces of both the internal insulating material (fiberglass) and the outside plastic envelope (now brittle pvc) are scattered about.

Our building is about 20 years old. At the time it was built, 20 years seemed like a long time off in the future. It doesn't any more. The building itself will be good for many more than 20 years, but the insulation is a huge liability at this point.

If the insulation is going to be covered on the inside by a sealed wall panel, perhaps it is ok. It will still split open and come apart, but as it breaks loose it will be contained by the two walls. However, it will loose its insulating value in walls as it will end up falling to the bottom instead of sticking to the wall. In roofs with only a moderate pitch, it will probably end up deposited on the inside covering, and maintain some of its insulating value.

Petroleum-product based fencing materials suffer similarly, degrading until they literally fall apart after about ten years and have to be removed.

|

|

| Cracks developing from

temperature stress on brittle pvc covering |

More advanced cracks |

|

|

| Insulation falling apart | 20 years on |